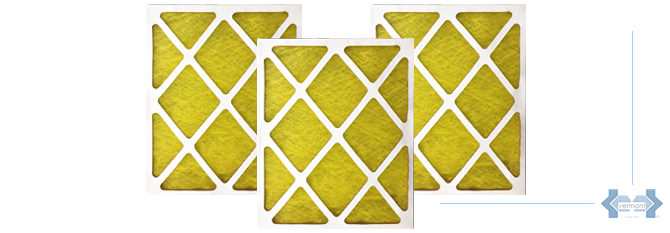

GENERAL: FDF disposable fiberglass filters are recommended for industrial, residential and commercial use.

MANUFACTURING: Vermont Fiberglass FDF filters are designed with progressive density filter fabric, standard measurements are 1″ nominal thickness (7/8″ accurate measurement), 2″ nominal (1-3/4″ exact measurement) and 4″ nominal. The fiberglass filter consists of continuous fiber filaments of 21 micrometers in diameter, joined with the filter fabric that is formed with layers of progressive density and which increases when the air flow increases from the inlet side of the flow to the side from the air outlet, where a layer of higher density is formed that helps retain more dust.. Each 1″ thick square foot weighs approximately 26 gr. And the 2″ thick weight is approximately 35 gr. The perforated sheet support grilles are corrosion resistant and are placed on both sides of the filter, both the mats and the support grilles are continuously glued throughout the perimeter of the frame, in this way we get excellent results in terms of filter stiffness and firmness. This design eliminates the possibility of the filter fabric sinking into the frame.

PHYSICAL DESCRIPTION

FABRIC: Progressive density fiberglass with colorless and odorless cover and layers.

SUPPORT: Corrosion-resistant perforated sheet metal on both sides of the filter.

ADHESIVE: Mixture of hot resin or glue.

FRAME: Made of sturdy cardboard.

IMPORTANT FEATURES

*Reinforced cardboard frame to prevent corners from being mistreated.

* Fabric filter and grilles continuously glued throughthe interior around the perimeter of the frame to provide rigidity.

*Available in special measures according to needs.

Notes:

1.- The tolerances available in the preparation of the filters are +0″, -1/4″ in height and width.

2.- The initial pressure drop is 0.07″ (C.A.) in the 1″ and 0.10″ (C.A.) filters For 2″. The recommended final resistance is 0.50″. (C.A.) But the system design can provide lower changes (outside these points). 3.- Average efficiency is 80% for 1″ and 82% for 2″ filters.

4.- These filters can be manufactured in 1″, 2″ and 4″ thick.